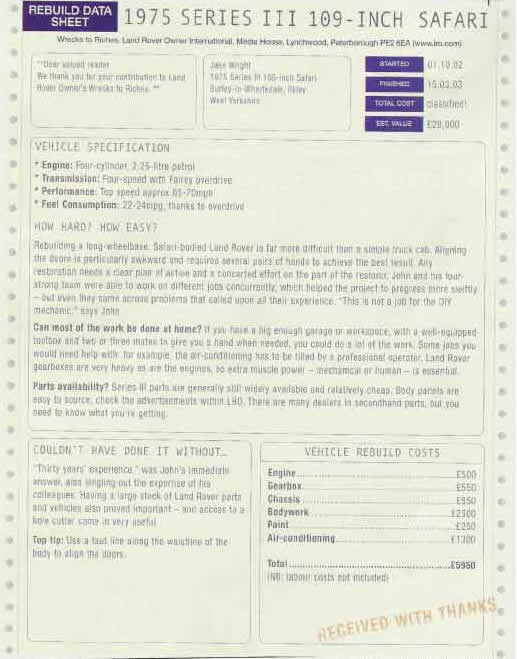

Fruit of his labours John Wright takes a last look at this peach of a 109, destined for life in the Big Apple

This superb 1975 109-inch is even cooler than it looks: its buyer in the USA specified air-conditioning to keep him cool in downtown New York. Mark Saville went to see it.

I'm a happy man. There are Land Rovers wherever I look, some of which are worthy of far more than just a quick once-over. There's a 4.2 V8-powered 90, a 100-inch truck cab with a Chevy engine and another 100-inch sporting an Iveco turbodiesel - all three built and owned by enthusiasts at Jake Wright Ltd, whose yard I happen to be in.

These guys know their Land Rovers. Over the past three decades, this family business has kept them running up hill and down dale - and there are plenty of both here in Wharfedale. They've also been involved in developing new ideas, like turbocharging 2.25 petrol Lightweights in the late '70s, for example.

John Wright, who runs the company, and his team are still keen to try out new ideas - which is just as well, really, seeing as how one of their recent projects has been the ground-up rebuild of this Series III 109-inch Safari, which included the fitment of an air-conditioning system for the USA-based customer.

It's fair to say that there hasn't been much penny-pinching. Every single component has been examined and either rebuilt or rejected in favour of a new item: that apparently standard exterior hides a multitude of subtle but useful modifications and improvements.

But no thrusting V8 transplant for this Land Rover: the customer insisted on keeping the 2.25 petrol engine, although it has been fitted with an overdrive. All well and good ... but why would someone choose to have an elderly Series III Safari imported to the USA instead of a newer, more civilised Land Rover such as, say, a One Ten Station Wagon?

There's a straightforward answer: all vehicles under 25 years old imported to the States are subject to stringent regulations, and modern Land Rover Station Wagons are one of many European models that are simply unable to qualify. Astonishingly, the last 500 110s that squeezed past the red tape some years ago now fetch upwards of $60,000 (about £37,600).

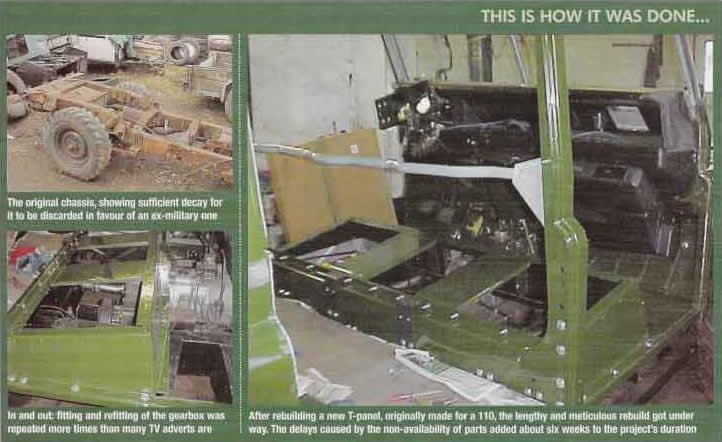

All restorations start with the lengthy process of taking the entire vehicle apart, spreading all the bits on the floor, and deciding (a) do you have enough good bits left to make a Land Rover? (b) do you have enough money to put it all back together? And (c) do you know how to put it back together? In this case the answer to (a) was most probably "no". Fortunately, both (b) and (c) were well taken care of.

Once the original vehicle was stripped of its dignity, the chassis was found to be beyond economical repair. The roof, rear side panels and windows, front wings and bonnet were all serviceable, as was the rear tub once the Jake Wright team had fabricated a new floor for it.

Squeezing in the condensor and the electric fan behind the grille provided a tricky challenge. X9 Superwinch has more than enough pulling power for boat-hauling duties

An ex-Ministry of Defence, civilian-pattern chassis was found and prepared for its new life under a tropical roof in the USA (it would later transpire to be a good choice). All the client's extra electrical goodies meant that fitting a new 65-amp alternator instead of the old dynamo would also come into the Very Good Idea category.

The X9 Superwinch specified for the front bumper can flatten a battery very quickly, so they fitted a split-charge system with two batteries.

However, with all the extra hardware for the air-con under the bonnet, there wouldn't be enough room for one battery, let alone two.

So, problem number one - where to put both batteries. The MoD always fitted an extra fuel tank under the passenger seats of its Series IIIs; this required substantial outriggers to be fitted. Although this was a civilian-pattern chassis, the MoD had carried out its standard conversion and fitted the second tank.

By creatively recycling this tank - cutting away the top of it - a new twin battery tray was formed. There - problem solved. Although the customer wanted to retain much of Ye Olde Worlde charm inherent in the Series III design, he was not so keen on frequent visits to his local chiropractor - medical treatment is very expensive in the USA - so new parabolic leaf springs were a priority, as they provide a far more supple ride than the original fitments. John swears by Rocky Mountain parabolics so that's what were used on this job.

Standard shock absorbers were retained because the vehicle won't need to make use of the increased axle articulation now available.

Goodyear Wrangler 7.50 R16s are visually similar in profile to the original 7.50 crossply tyres, which is why this size was chosen - wide-boy alloys and big rubber don't fit in with the classic look wanted by the client - and the Goodyears also provide a good on-road/off road balance.

Tight fit: after carefully rearrangement of the usual bits round under the bonnet of a Series III, the new compressor for the air conditioning slotted in neatlyThe original engine hadn't survived the passage of time very well and, with a strong ex-MoD, reconditioned unit available, the decision was easy. Once it had been checked thoroughly and a new clutch had been fitted, it was slotted in between the chassis rails. A Fairey overdrive was bolted to the totally rebuilt gearbox.

After close inspection, the original axles were retained, with the addition of Selectro freewheeling hubs on the front. The build-up continued with the refitting of the bulkhead, which had benefitted from an in-house grit blasting and a new coat of paint.

Long-wheelbase Station Wagons are the hardest Land Rovers of all to rebuild, mainly because they have a lot more bits to their bodywork - and many of these bits have a habit of crumbling away into rust.

A case in point with this vehicle were the rotted B-pillars between the front and rear side doors. These are, in fact, in an inverted "T" shape, which is why they're also referred to as T-panels. And it was these panels that caused the Jake Wright team their first really big problem. They had one in stock but the other had to be ordered from Land Rover.

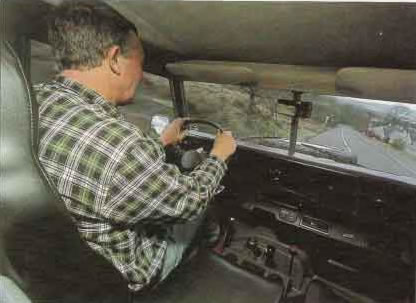

On the pull: the shorter black gearstick control the overdrive essential for long trips in the US. The knee-height air-conditioning panel takes up a lot of precious roomAfter waiting six weeks, it became clear that the project was being unreasonably delayed - time to move on. John knew that the T-panel from a Defender 110 is fundamentally the same, albeit with a few extra holed. It costs £150 more than a Series III item, but - reluctantly - he ordered one.

When it arrived, it was distorted, so John took the panel apart and remade it, at last endowing him with a matching pair of T-panels. Five new doors were ordered from SPI in Warwick and fitted to the growing bodywork - a wash-wipe kit from Pacet was also added to the new rear door in order to keep the heated rear screen clean. The original front split-screens have been retained, but they are now glazed with heated glass. These standard Land Rover parts cost £200 per pair, plus wiring. They should be considered every bit as much an essential purchase as the air-con: New York winters are as bitingly cold as the summers are stifling.

Once the bodywork was finally assembled, it received several coats of ICI's Deep Bronze Green which, although not perhaps a perfect match for Land Rover's version, is very attractive all the same, with the Limestone-painted tropical roof really looking the part.

The galvanised exterior trim was thoroughly cleaned rather than re-dipped, which helps the vehicle retain some of its original patina.

The vulnerable rear corners of the Series III bodywork are protected by Defender-style bumperettes, which are a little too deep for the cross-member, so the mudflaps were moved further back to disguise this.

The X9 Superwinch sitting on the front bumper gives a purposeful appearance to the vehicle, as well as providing a means of retrieving the owner's boat from the river - the main reason it's there in the first place. So much for the exterior, then - but what's it like inside?

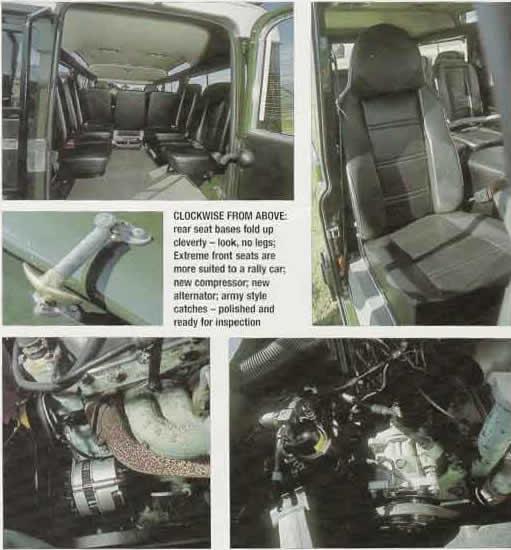

Land Rover seats of the 70's are not known for their comfort over long distances, so new vinyl-trimmed seating from Exmoor Trim has been fitted throughout. Black vinyl was chosen instead of cloth, mirroring the original look as well as being easy to clean. The front seats are the new Extreme versions, which to my eye don't really suit the rest of the interior - the built-in head restraints give an incongruous rally-car look and they're a bit narrow, too. The remaining seven seats are the high back variety, which look altogether more in keeping, and everybody benefits from modern Securon seatbelts to keep them secure.

In the front, the air-conditioning dashboard panel is the most obvious modification (the conversion to left-hand drive notwithstanding). The reduced kneeroom is upfront and obvious - the panel and its controls are both straight out of a left-hand-drive Defender Td5, where it causes similar restrictions.

The front middle seat has been replaced by a lockable centre cubby box, which includes the all-important cup holders for those drive-thru double lattes. Exmoor Trim also supplied thick, grey matting for the floot that's not only easily cleaned, but also deadens sound entering the cab. The seatbox is similarly covered.Fortunately, because the centre bulkhead is deleted from the 109-inch Safaries and replaced by a stylish handrail, the front seats are at least able to move a little further back than in other models.

Fitting the business end under the bonnet caused a few headaches, as John explains. The front panel had to be cut out to allow the condenser and fan unit to fit in. Brackets had to be made up to allow the steering arm to operate underneath it.

"The underbonnet catch assembly couldn't be used because the new condenser and electric fan were in the way, so we opted for army-type catches, mounted outside, instead. We also had to move the air filter forward to where the battery usually sits."

New rear wash-wipe added to keep heated screen clean The air filter wasn't the only item to move to a new home: the air- conditioning compressor sits where the dynamo used to, thanks to a modified bracket purloined from a 24v MoD alternator.The new alternator now hangs from the lower, right-hand-side of the block; and lining up all these pulley's was a task in itself.

However, it has to be said that all the benefits of air-conditioning far outweigh any of the disadvantages, particularly in a hot, humid climate. After a trip to a local air-conditioning supplier to get the system charged up, it was time to test it out.

It has two simple controls - a rocker switch, which operates the three-speed fan, and a variable control to select the temperature. The unit's fan is completely separate from the standard heater/blower. Air is drawn into the evaporator unit in the front passenger footwell, where it is cooled before being pumped out through the dash vents.

"Although the weather in Yorkshire isn't as hot as summertime New York, the system can certainly pump out enough cold air to keep people cool. We're looking forward to hearing the customer's comments on this after he takes delivery," says John.

A critical factor to the successful operation of any air-conditioning system is the sealing of all the windows and doors. And, of course, making a Series III 109-inch Safari airtight is about as easy as carrying water in a string vest.

This particular Safari, however, benefits from thick, new rubber seals throughout, which make closing any one of the five doors a challenge. While driving along, the interior is entirely draught-free, which indicates that most holes have been plugged - and that certainly augurs well for the performance of the air-con on the eastern seaboard of the US.With the vehicle complete after five months' work, all it needed was a brief road test before heading for the docks. And here came a reminder that even the most professional, experienced Land Rover rebuilders can encounter unforseen problems.

After a short trip around the block, John was unhappy with the gearbox. Despite its complete rebuild with completely new innards, it wasn't completely quiet.

So much for the "brief" road test. Out came the gearbox, followed by a stripdown. The errant noise was found to be coming from a layshaft gear - normally they have the edge machined to prevent this but, for some reason, this one hadn't been thus treated. One machined edge later, it was time for road test No 2.

A labour of love for John - thorough road test for his latest pristine project

After a few miles, the clutch pedal became soft, leaving the Land Rover stuck in gear. By selecting low range, then restarting in gear, John was able to drive gingerly back to the workshop.

Of course, a soft clutch pedal is always caused by a leaking seal. Well isn't it ...? Usually the answer is yes, but today the answer was no. After another test run, during which the clutch failed again, the slave cylinder was replaced. Yet another test run - with the same result.

Out came the gearbox again. The clutch was removed and mounted on to a flywheel on the bench. The problem was clear - the fingers of the diaphragm spring were all at different heights, which is what caused the clutch to malfunction. There's a clear moral: when fitting any new clutch, always check this before putting the gearbox back in.Original Borg and Beck clutches are no longer available, but John headed for his Aladdin's Cave-like parts store, where resided a clutch for a 2.6-litre six-cylinder. With just a little modification, he was sure it would fit the 2.25.

Needless to say, it did; and the 109 is at last New York-bound.